An efficient Solar Cocoa-Drier

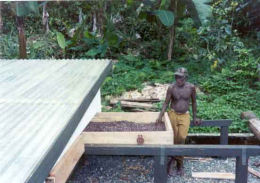

Describing the building of a small, solar-drier for village-level commercial use. Based on actual project experience within the Solomon Islands, the resulting drawings could be adapted to other tropical areas, perhaps up to 25° latitude.

There are two similar designs offered; one featuring a lean-to model best suited to gently sloping terrain (the actual prototype) with suggestions for another, larger model more suited to level ground.

Purpose. The quality of fire-dried cocoa and copra has always been, and is increasingly more so, an issue with end-buyers. The normal method of drying the fresh harvest at the village level is over slow-burning fires contained in steel oil-drums. This may result in smoke-tainting, lower prices and even rejection.

Fire-drying is labour intensive and wasteful. It requires lots of firewood and regular tending. One sack of output requires inputs about every 4-6 hours, normally for 3 days. This is the universally employed method for cocoa production in the Solomon Islands.

Village Production. Solar-drying of cocoa is a viable option to fire drying (‘hot-air'). Most Solomon families do not own a ‘hot-air drier'. Either they use their relatives' or just sell their harvest (wet bean) direct to a neighbour who processes and on-sells it to a contractor.

Political Background. During the nationwide disruption from ethnic clashes in Guadalcanal 1998 – 2000 the internal economy collapsed, as did commodity export production. This coincided with a sharp slump in copra prices, and a modest rise in cocoa prices. Since then privatisation of the commodity exporting industry and a steady rise in cocoa prices has seen many farmers put their cocoa plantations back into production and a strong growth in cocoa plantings.

Conclusion. The project outlined here is considered a very successful demonstration of the practicality of solar-drying cocoa as a commercially-viable proposition for village-level enterprise.

- improved product quality

- reduced drying time & effort

- reduced environmental impact

By experimenting with the design further improvements to the de-moisturing efficiencies, maintenance levels and produce handling are likely.