History of the Project

Background

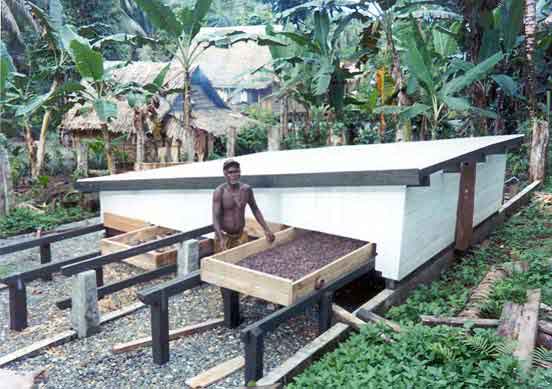

This project arose from recognising an opportunity to help rural Solomon Islanders to realise significantly better incomes. National export earnings are predominantly from copra, cocoa and timber production. Coconut plantations are very widespread, and quite a few areas have extensive cocoa plantings as well. However, outputs are limited by the high labour content in the post-harvest processing.

It was conceived as a copra-drier at a time when copra prices were reasonably good. It was expected that even if solar drying was unable to reduce moisture content to the required 10% it would nevertheless be able to

It was conceived as a copra-drier at a time when copra prices were reasonably good. It was expected that even if solar drying was unable to reduce moisture content to the required 10% it would nevertheless be able to

save at least 2 of the 3 days normally needed for drying it over a fire.

Processing of cocoa, fruit & fish for commercial, or local consumption were other possibilities, but inadequate or seasonal input supplies and pre-drying preparation were seen as limitations in these cases.

The concept was to co-build a drier unit and storage shed with the new owner-operator, test it, then use that experience to design an improved model and have the next one self-built by a different owner from plans similar to those included in this manual – to test the information transfer process.

Economic context. The prototype drier took much longer to build than expected, but over that period the $SBD* value of cocoa rose by more than 5 times. Only about 40% of that was due to devaluation in the local currency, the rest reflected international market prices.

These economic changes affected the direction of the project. The commodity of interest became cocoa which required much more preparatory processing.

In relative terms, copra prices have since remained depressed while cocoa prices have climbed even higher.

* $SBD = Solomon Island dollar